Week 5 - Learning Sheet Metal, New Design Structures, System Production Analysis

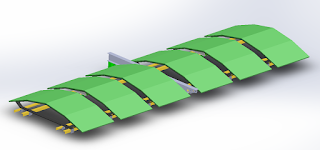

This week we learned how to use sheet metal in SolidWorks. In addition, we analyzed the system production of a solar system that was 2000 m long and 4 panels across. We then compared our results to determine if these results to determine how close they were to an excel spreadsheet setup. It was determined that the results were close enough. The differences are due to different input panels and inverters, as well as other setup parameters. Also, We worked on new designs that would be more visually pleasing to riders, such as arched sheet metal on the side instead of previously proposed flat panels. The top could remain the same as previous designs we have proposed in week 3.